Storz System Couplings and Hoses

Storz system hose couplings are often referred to as fire department couplings.

They are symmetrical, non-shut-off couplings.

The couplings are connected by inserting the lug parts into each other and twisting them against each other. The connection fittings to be coupled are identical on the coupling side and can be connected in any way, provided they are the same size.

Application area:

for industry, fire department, refineries, agriculture, construction, shipping, military, and disaster control

Application:

- for sealing couplings of the appropriate size

- Quick connection and disconnection with a 120° turn

Suction coupling:

Suction couplings are used for connecting suction hoses.

Fixed coupling:

Fixed couplings (threaded pieces in many variants) are used for connecting hoses to fittings. They are firmly screwed on one side with a pipe thread on a water-carrying fitting or a hydrant. On the other side, the usual couplings of a pressure hose or a suction hose can be connected.

Blind coupling:

Blind couplings (i.e., end caps for temporarily unused Storz connections) are used as an end on fittings to protect them (e.g., against the ingress of dirt into pumps) and must not be pressurized if the line cannot be relieved (risk of accident when loosening the blind cap under pressure).

Coupling wrench made of steel for Storz sizes A/B/C

- Material: Steel

- for Storz sizes A/B/C

- with cold protection

Construction and industrial hose A/102, B/75, C/52, D/25 in various lengths:

Color: outer white

Material: Outer: polyester yarn, round woven, warp 2-ply twisted

Operating pressure: 10 bar

- with Storz suction couplings

- Wire binding

- uncoated

- Protective sleeve to prevent chafing at the hose coupling

User information:

This operating manual must be read carefully before first use and observed during use.

1. General information on flat or pressure hoses

Pressure hoses have the primary task of liquid transfer, especially water.

However, they can also be used to drain wastewater or similar. They consist of round-woven plastic fibers (in this case polyester) and are coated inside.

A significant advantage of flat hoses is their low weight and flexibility, which makes them easy to fold and transport when not under pressure.

2. During use

Due to their primary task and predominant areas of use, flat hoses are subject to high external influences that can shorten their lifespan.

For optimal service life, the following is recommended:

- Do not exceed the maximum operating pressure.

- When laying the hoses, ensure that they are unrolled if possible. Otherwise, always pull them flat. This can prevent the hose from dragging on the edge on the ground and immediately damaging the hose cover.

- Avoid rough surfaces if possible.

- Do not pull hoses over sharp-edged, pointed objects and/or surfaces.

- Never drop hose ends or fittings, as this can cause damage to the lugs or the fittings themselves.

- Do not pull or drag hoses under pressure on the ground, as the resulting abrasion can damage the hose cover. Vibrations of hoses under pressure can be reduced or absorbed using accessories, e.g., burlap, tarpaulins, or bandages.

- If hoses are to be used at transitions, hose bridges should be used. Hoses should never be driven over or stepped on.

- Keep hoses away from acids, chemicals, and hazardous substances if possible.

3. After use:

To ensure the longevity of the hoses, the following instructions should be observed after use:

- To remove the residual amounts of the liquid medium from the hose, the hose should be lifted over the shoulder. Never step on the hose!

- After use, free hoses from deposits inside the hose (sand, etc.), i.e., rinse them out. They should then be dried (otherwise mold/lime can deposit inside the hose, which can permanently damage the core).

- Clean the hose cover from external dirt.

- Hoses must never be stored in a damp condition.

- Check fittings for integrity.

- Store hoses in a rolled-up condition if possible.

- When rolling up, ensure that the hoses do not drag on rough surfaces, as when unrolling.

|

Article |

Connection |

Material |

Size |

Lug Distance |

Working Pressure |

|

D Coupling with Spigot |

Suction coupling with hose spigot |

Aluminum |

25 mm |

31 KA |

15 bar |

|

C Coupling with Spigot |

Suction coupling with hose spigot |

Aluminum |

50 mm |

66 KA |

15 bar |

|

B Coupling with Spigot |

Suction coupling with hose spigot |

Aluminum |

75 mm |

89 KA |

15 bar |

|

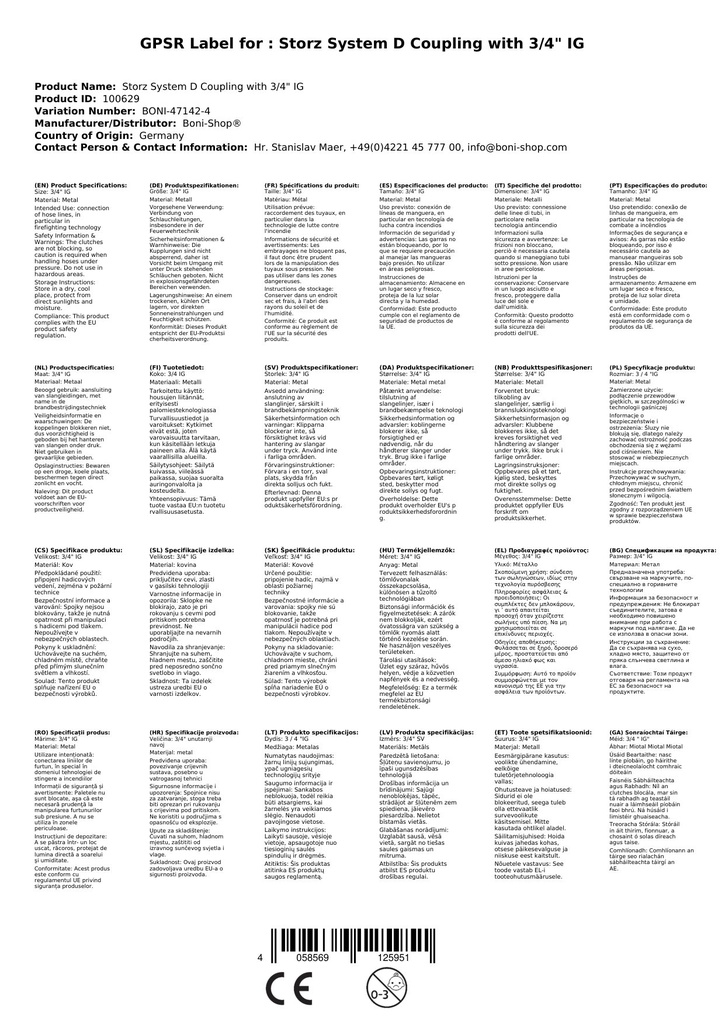

D Coupling with 3/4" IG |

Fixed coupling with internal thread |

Aluminum |

3/4 inch |

31 KA |

15 bar |

|

D Coupling with 1" IG |

Fixed coupling with internal thread |

Aluminum |

1 inch |

31 KA |

15 bar |

|

C Coupling with 1" IG |

Fixed coupling with internal thread |

Aluminum |

1 inch |

66 KA |

15 bar |

|

C Coupling with 1 1/4" IG |

Fixed coupling with internal thread |

Aluminum |

1 1/4 inch |

66 KA |

15 bar |

|

C Coupling with 1 1/2" IG |

Fixed coupling with internal thread |

Aluminum |

1 1/2 inch |

66 KA |

15 bar |

|

C Coupling with 2" IG |

Fixed coupling with internal thread |

Aluminum |

2 inch |

66 KA |

15 bar |

|

B Coupling with 2" IG |

Fixed coupling with internal thread |

Aluminum |

2 inch |

89 KA |

15 bar |

|

B Coupling with 2 1/2" IG |

Fixed coupling with internal thread |

Aluminum |

2 1/2 inch |

89 KA |

15 bar |

|

B Coupling with 3" IG |

Fixed coupling with internal thread |

Aluminum |

3 inch |

89 KA |

15 bar |

|

D Coupling with 1" AG |

Fixed coupling with external thread |

Aluminum |

1 inch |

31 KA |

15 bar |

|

C Coupling with 1" AG |

Fixed coupling with external thread |

Aluminum |

1 inch |

66 KA |

15 bar |

|

C Coupling with 1 1/4" AG |

Fixed coupling with external thread |

Aluminum |

1 1/4 inch |

66 KA |

15 bar |

|

C Coupling with 1 1/2" AG |

Fixed coupling with external thread |

Aluminum |

1 1/2 inch |

66 KA |

15 bar |

|

C Coupling with 2" AG |

Fixed coupling with external thread |

Aluminum |

2 inch |

66 KA |

15 bar |

|

B Coupling with 2" AG |

Fixed coupling with external thread |

Aluminum |

2 inch |

89 KA |

15 bar |

|

B Coupling with 2 1/2" AG |

Fixed coupling with external thread |

Aluminum |

2 1/2 inch |

89 KA |

15 bar |

|

B Coupling with 3" AG |

Fixed coupling with external thread |

Aluminum |

3 inch |

89 KA |

15 bar |

|

D Blind coupling |

Blind coupling with chain |

Aluminum |

- |

31 KA |

15 bar |

|

C Blind coupling |

Blind coupling with chain |

Aluminum |

- |

66 KA |

15 bar |

|

B Blind coupling |

Blind coupling with chain |

Aluminum |

- |

89 KA |

15 bar |

|

Reduction C-D |

Transition piece from C to D |

Aluminum |

- |

66 KA to 31 KA |

15 bar |

|

Reduction B-C |

Transition piece from B to C |

Aluminum |

- |

89 KA to 66 KA |

15 bar |

|

Reduction A-B |

Transition piece from A to B |

Aluminum |

- |

133 KA to 89 KA |

15 bar |

|

D Nozzle |

Spray nozzle type 25D |

Aluminum |

2 inch1 inch |

31 KA |

- |

|

C Nozzle |

Spray nozzle type 52C |

Aluminum |

2 inch |

66 KA |

- |

|

D Gasket |

Gasket type Storz |

NBR |

31 KA |

- |

|

|

C Gasket |

Gasket type Storz |

NBR |

66 KA |

- |

|

|

B Gasket |

Gasket type Storz |

NBR |

89 KA |

- |

|

|

A Gasket |

Gasket type Storz |

NBR |

133 KA |

- |

|

Thread sizes conversion inches to mm (mm in approx. indication) |

|

|

1/4 inch |

12.5 mm |

|

3/8 inch |

16 mm |

|

1/2 inch |

19 mm |

|

3/4 inch |

26 mm |

|

1 inch |

32 mm |

|

1 1/4 inch |

40 mm |

|

1 1/2 inch |

48 mm |

|

2 inch |

59 mm |

Note: May show small scratches or streaks due to production!