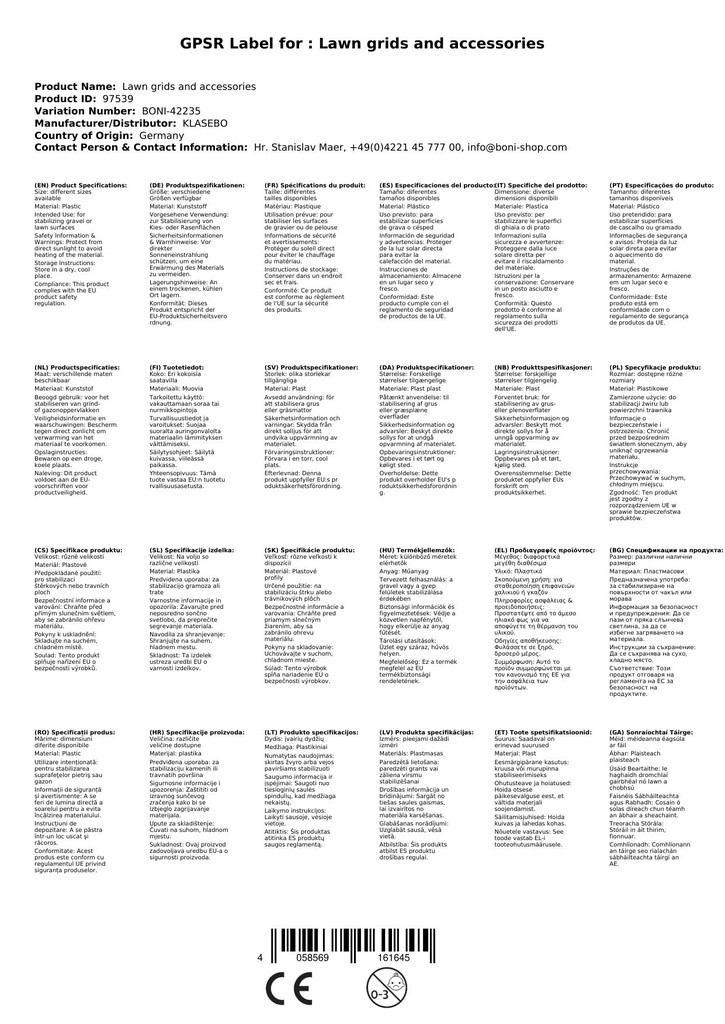

Grass Grids and Accessories

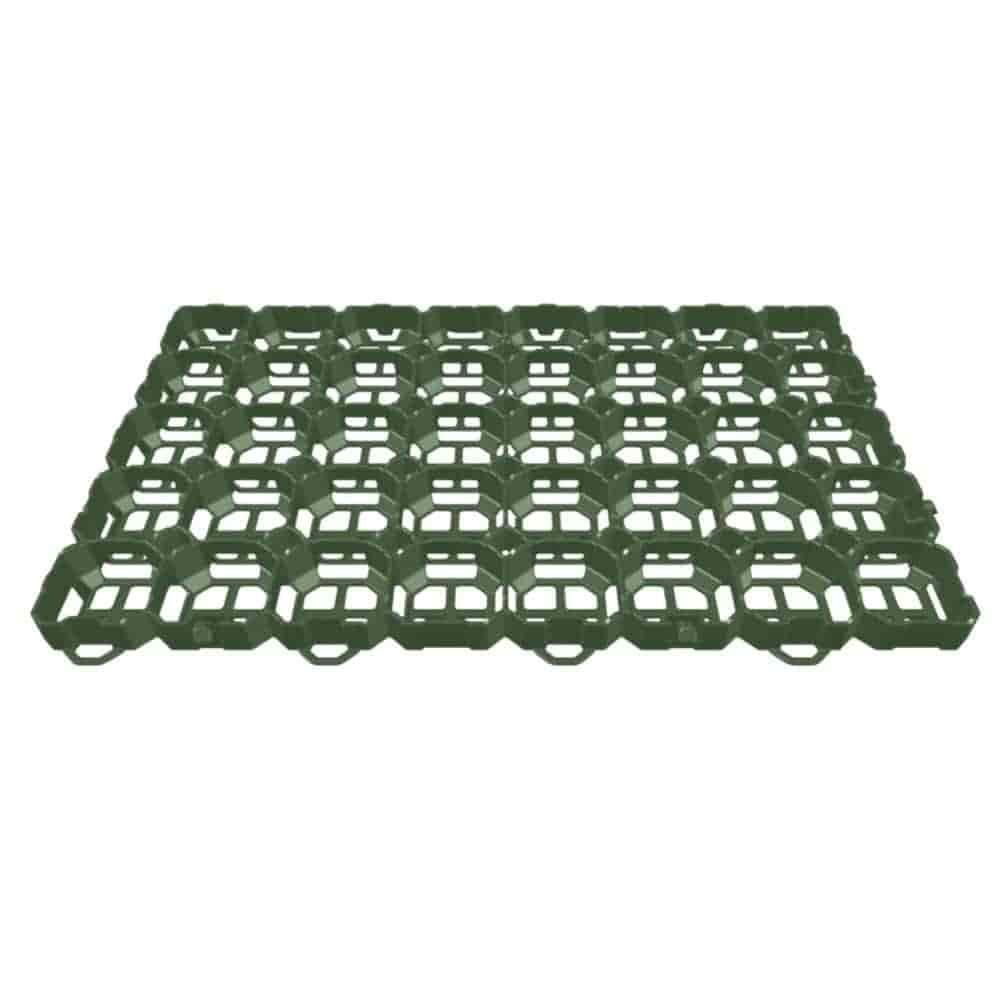

With our innovative grass gravel grids in various colors and strengths, you will find the right solution for every application! Prefer stable gravel or grass areas rather than concrete or paving. Due to the open structure, these grids offer ideal conditions for grass growth. Lateral openings in a honeycomb pattern allow the grass to root extensively. Water simply seeps through and ensures a more natural water and nutrient balance compared to sealed surfaces.

Our grass gravel grids can be used to reinforce driveways, parking lots, and other heavily used grass/gravel areas. Slopes can also be stabilized this way.

Made from already 100% recycled materials, which can be recycled again, our grids are completely environmentally neutral!

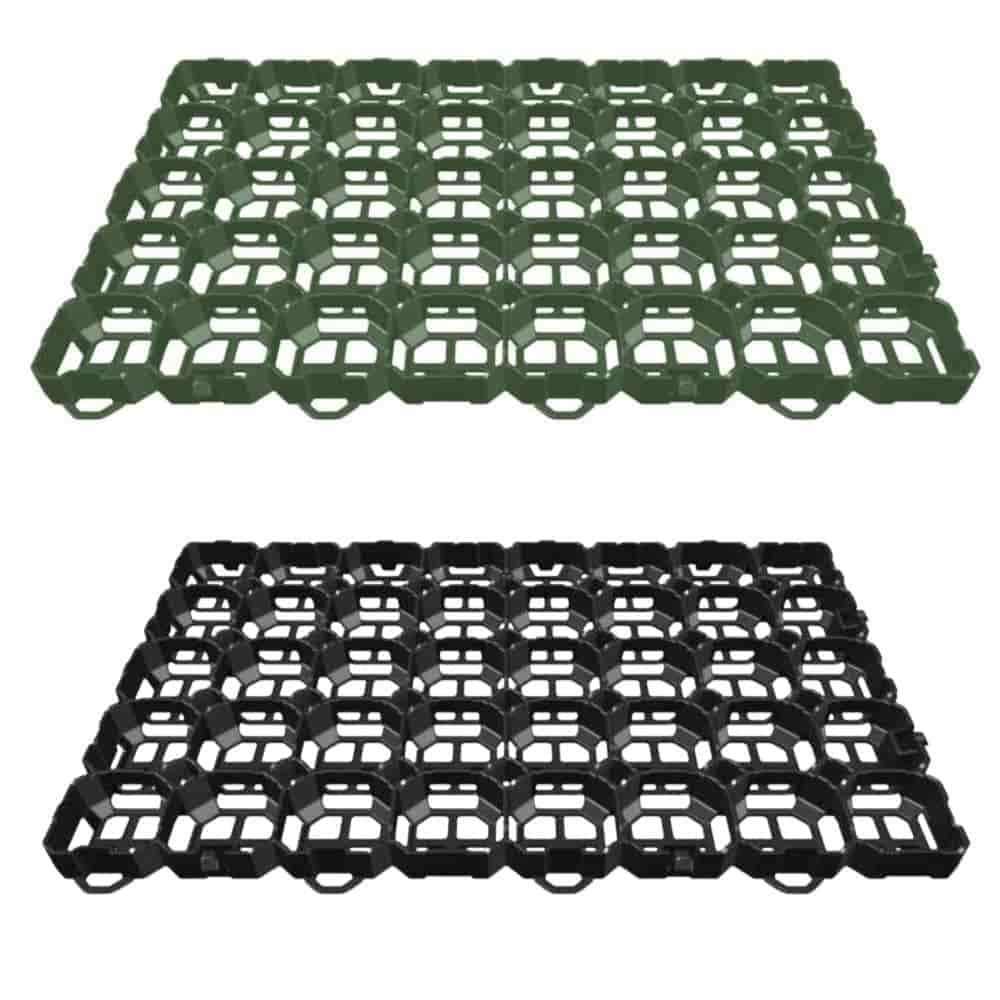

Grass grids in various designs:

- Green plastic grass gravel grid - RKP1 (approx. 49.2x49.2x4cm)

- Black plastic grass gravel grid - RKP1 (approx. 49.2x49.2x4cm)

- Green plastic grass gravel grid - RKP2 (approx. 49.2x49.2x5cm)

- Black plastic grass gravel grid - RKP2 (approx. 49.2x49.2x5cm)

- Green plastic grass gravel grid - RKP6 (approx. 57x38x4cm)

- Black plastic grass gravel grid - RKP6 (approx. 57x38x4cm)

The ecological alternative to concrete surface sealing:

- Made from 100% recycled material - Environmentally neutral - 100% recyclable!

- Driveable by fire trucks according to DIN EN 1072:1985

- TÜV tested!

- Easy laying thanks to low weight, practical hook system, and spikes on the bottom

- Easy processing of the grids with standard angle grinders or hand/jigsaws

- Further fixation possible through additionally available plastic hooks

- Marking of parking spaces or other areas possible with insertable white plastic plates (accessories)

Processing:

- Using the four earth spikes on the bottom, the individual grass grids can be easily and stably fixed to the ground.

- Simple connection of the grids through the side hook system.

- The shape and size of the grass grids can be easily adjusted with standard jigsaws or angle grinders.

- A stable, compacted, and water-permeable ground structure (gravel or crushed stone mix) is essential as with other flooring.

- The respective area must be excavated and mechanically compacted to a depth of about 30 to 40 cm, depending on the load.

- After compaction, the area is filled with a gravel or crushed stone layer (15-30 cm) and compacted mechanically again. This creates the ground structure.

- For areas driven over by vehicles up to 3.5 tons, a leveled compensatory sand layer of 5-7 cm should be laid over fleece (100g/m²).

- With gravel or crushed stone filling, the area can be driven over immediately. With grass filling, the area can be driven over after about 6 weeks.

- The grass grids are suitable for gravel or grit fillings with a maximum grain size of 20 mm and offer an economical solution that also saves a lot of work.

Application examples:

- Driveways

- Parking lots

- Entrances

- Heavily walked-on grass areas

- Campsites

- Paddock areas

- Garden/park paths

- Stabilization of slopes

- Bicycle paths

- Green roofs

Note:

The manufacturer allows color tone differences among individual elements. This is a typical characteristic of products made from recycled material. The color tone does not adversely affect the quality and parameters of the product. Color changes during use are a natural process that products made from recycled material can undergo. These changes do not affect the quality of the goods in any way.